One of the companies Ford is teaming up with is 3M and together, they aim to produce a new kind of Powered Air-Purifying Respirator or PAPR for frontline workers. From this partnership, 3M is also increasing the production of its current respirator device.

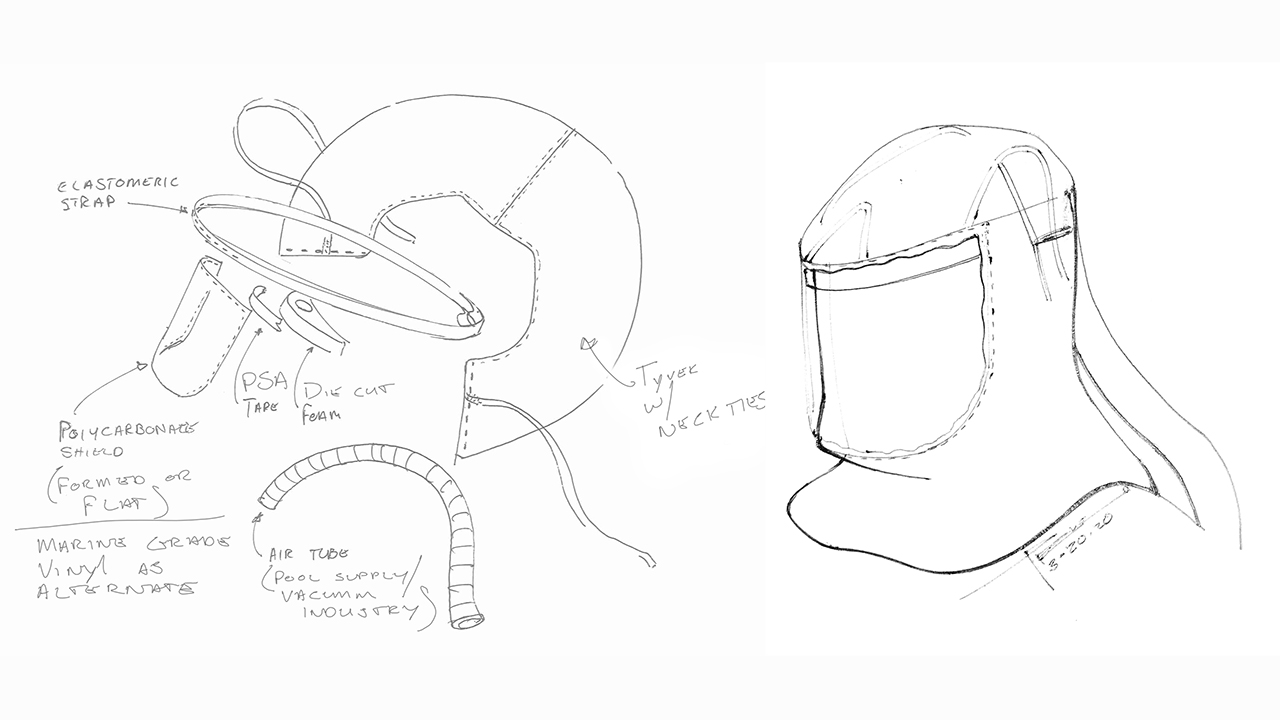

How the Powered Air-Purifying Respirators work is through a clear mask fitted over the face of the patient. Air is then drawn in through a tube and goes to a filtration system before delivering clean air to the patient.

To make this possible, Ford opted to use fans from its F-150 which are responsible for cooling its seats and repurposed them to direct airflow to the ventilator’s internal chamber. 3M’s HEPA air filters then clean the delivered air and are planned to be powered by battery packs that could last up to eight hours. Ford is also working with other companies to provide batteries to power the PAPRs.

Additionally, GE Healthcare is also working hand-in-hand with Ford to further increase ventilator and air pump production. According to Ford President and CEO Jim Hackett, we should be seeing hundreds of thousands of ventilators come May this year.

The United Auto Workers (UAW) Union is also in the picture for the assembly of more than 100,000 clear plastic face shields per week.

Hackett said that history provided motivation for this movement. In the past, Ford has been involved in projects like building helmets and aircraft during World War I and World War II, respectively, and iron lungs for polio patients.

Ford Executive Chairman Bill Ford also adds that this outbreak is a chance for people to work together.

“This is such a critical time for America and the world. It is a time for action and cooperation. By coming together across multiple industries, we can make a real difference for people in need and for those on the front lines of this crisis,” said Bill Ford, Ford’s executive chairman. “At Ford, we feel a deep obligation to step up and contribute in times of need, just as we always have through the 117-year history of our company.”

Ford is not the first automotive company to lend help to fight coronavirus. General Motors also revealed their plans to partner with other companies to produce ventilators. Meanwhile, Fiat Chrysler Automobiles pledged as many as one million protective face masks per week to donate to frontline workers who are usually exposed to the virus.